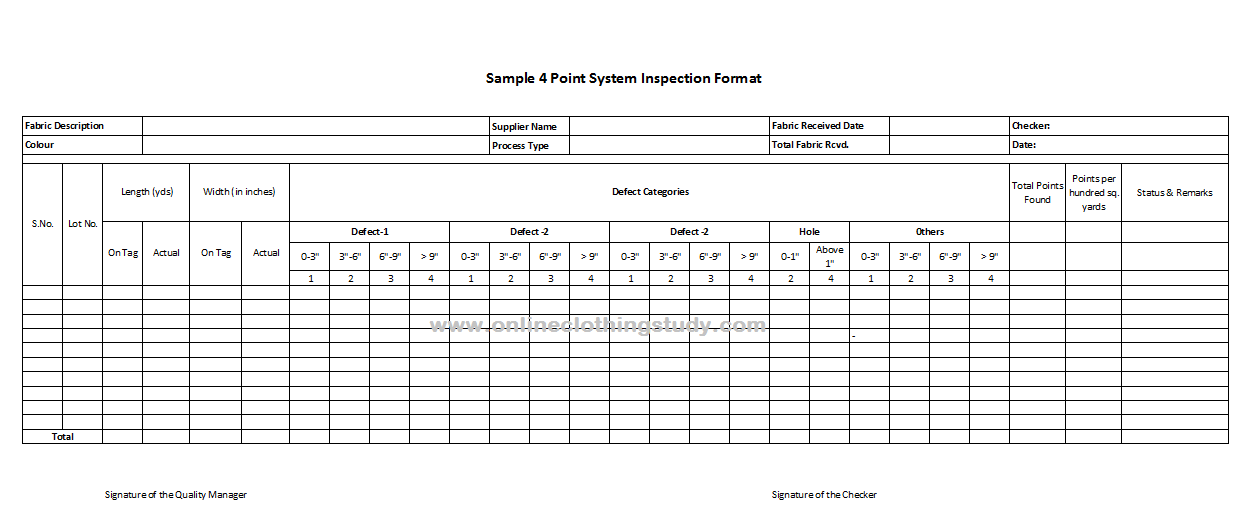

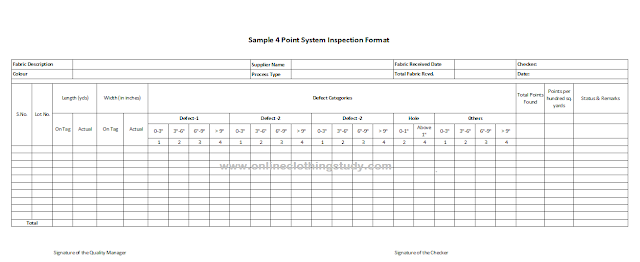

Fabric Inspection Report Format In Excel. A sample 4 point system fabric inspection format has been attached at the bottom. Final inspection is the last steps of garment inspection system. Fabric checker should know common defects found in fabrics and he must recognize defects on the fabric at the time of fabric inspection. Some basic formats used by various departments such as merchandising, fabric store, cutting room, sewing floor, work study, quality audit and finishing department are listed here.

Daily Production Report Excel Template (Free Download) From onlineclothingstudy.com

Daily Production Report Excel Template (Free Download) From onlineclothingstudy.com

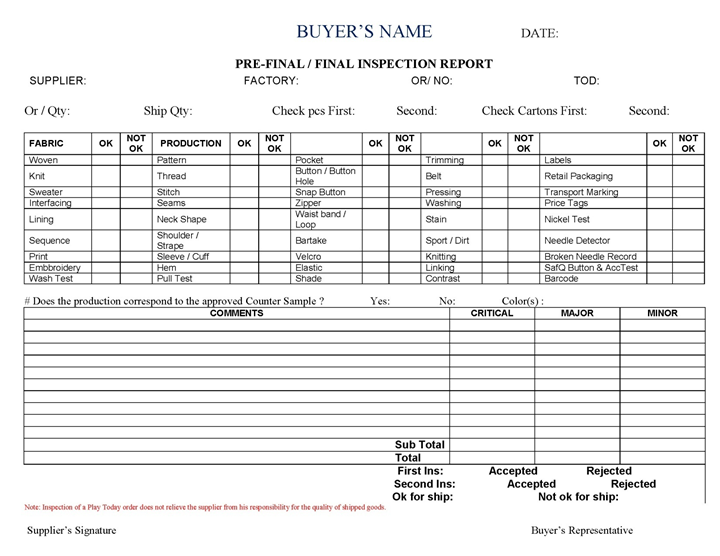

Download the file after opening it on google drive to use the template. Final inspection is very important. Types of defects found in fabric. Quick and easy first article inspection report software with our free first article inspection report (fair) forms, you can manually complete to fill the forms on excel or other spreadsheet software. I assume that you are one of them. In this stage complete garments are inspected by buyer.

Different parts of garments are inspected in this stage such as garments main fabric, accessories, trims, label, fabric faults etc.

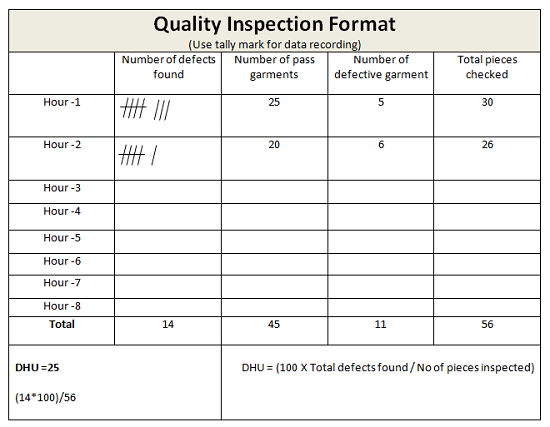

Use tally marking for recording of number of defects. I assume that you are one of them. Some of the formats are image files. There are various systems for final inspection in the garment industry. After opening those image files, save (ctrl+s) on your computer. Fabric checker should know common defects found in fabrics and he must recognize defects on the fabric at the time of fabric inspection.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

Use tally marking for recording of number of defects. Different parts of garments are inspected in this stage such as garments main fabric, accessories, trims, label, fabric faults etc. Some files are uploaded on google drive and shared. After opening those image files, save (ctrl+s) on your computer. Use pivot table and become smart in report making (download excel template) report making is one of the daily activities for most of the garment manufacturers in the garment industry.

Source: textilelearner.blogspot.com

Source: textilelearner.blogspot.com

2 defects between 6” to 9” 2 x 3 = 6 points. There are various systems for final inspection in the garment industry. Calculate defects per hundred units (dhu) dhu = (totals defects found x 100)/total pieces checked. Use tally marking for recording of number of defects. Ahu pm checklist (air handler unit hvac)ahu tasks.

Final inspection is very important. 6 defects between 3” to 6” 6 x 2 = 12 points. Some of the formats are image files. Fabric inspection is the systematic observation of fabrics to decide if it meets the client specification such as count/construction, color, design, measurement specifications, hand feel, and other specific quality parameters. Purchase includes pm checklists in excel format for the following 27 equipment types:

Source: db-excel.com

Source: db-excel.com

Final inspection is the last steps of garment inspection system. 4 defect below 3” 4 x 1 = 4 points. See more ideas about kpi dashboard excel,. Calculate defects per hundred units (dhu) dhu = (totals defects found x 100)/total pieces checked. Purchase includes pm checklists in excel format for the following 27 equipment types:

Source: pinterest.com

Source: pinterest.com

2 defects between 6” to 9” 2 x 3 = 6 points. See more ideas about kpi dashboard excel,. There are various systems for final inspection in the garment industry. 2 defects between 6” to 9” 2 x 3 = 6 points. Download the file after opening it on google drive to use the template.

Here is some free excel template ready to download. Sum up total pieces checked and total defects found in those checked pieces. By using mis system (reports) managers can measure work, track information on the right time and in the right form. 1 defect more than 9” 1 x 4 = 4 points. Quality inspection data collection format.

Some fabric defects are given below: See more ideas about kpi dashboard excel,. Types of defects found in fabric. Final inspection is the last steps of garment inspection system. During textile and apparel inspections, intertek conducts the following:

Source: wendangwang.com

Source: wendangwang.com

Use tally marking for recording of number of defects. 6 defects between 3” to 6” 6 x 2 = 12 points. In this stage complete garments are inspected by buyer. 4 defect below 3” 4 x 1 = 4 points. We have developed an excel (inventory management) template for your convenience.

Different parts of garments are inspected in this stage such as garments main fabric, accessories, trims, label, fabric faults etc. Quick and easy first article inspection report software with our free first article inspection report (fair) forms, you can manually complete to fill the forms on excel or other spreadsheet software. Some basic formats used by various departments such as merchandising, fabric store, cutting room, sewing floor, work study, quality audit and finishing department are listed here. 2 defects between 6” to 9” 2 x 3 = 6 points. Download the file after opening it on google drive to use the template.

Source: old.digitaleng.news

Source: old.digitaleng.news

See more ideas about kpi dashboard excel,. Use pivot table and become smart in report making (download excel template) report making is one of the daily activities for most of the garment manufacturers in the garment industry. Final inspection is the last steps of garment inspection system. Fabric inspection is the systematic observation of fabrics to decide if it meets the client specification such as count/construction, color, design, measurement specifications, hand feel, and other specific quality parameters. Different parts of garments are inspected in this stage such as garments main fabric, accessories, trims, label, fabric faults etc.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

Fabric inspection is the systematic observation of fabrics to decide if it meets the client specification such as count/construction, color, design, measurement specifications, hand feel, and other specific quality parameters. 2 defects between 6” to 9” 2 x 3 = 6 points. Types of defects found in fabric. Quality inspection data collection format. Here is some free excel template ready to download.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

4 defect below 3” 4 x 1 = 4 points. Sum up total pieces checked and total defects found in those checked pieces. See more ideas about kpi dashboard excel,. Some files are uploaded on google drive and shared. Fabric checker should know common defects found in fabrics and he must recognize defects on the fabric at the time of fabric inspection.

Source: pinterest.se

Source: pinterest.se

Ahu pm checklist (air handler unit hvac)ahu tasks. Quick and easy first article inspection report software with our free first article inspection report (fair) forms, you can manually complete to fill the forms on excel or other spreadsheet software. Purchase includes pm checklists in excel format for the following 27 equipment types: Types of defects found in fabric. 4 defect below 3” 4 x 1 = 4 points.

Source: pinterest.co.uk

Source: pinterest.co.uk

Some of the formats are image files. 6 defects between 3” to 6” 6 x 2 = 12 points. We have developed an excel (inventory management) template for your convenience. Sum up total pieces checked and total defects found in those checked pieces. Some fabric defects are given below:

Source: pinterest.com.mx

Source: pinterest.com.mx

During textile and apparel inspections, intertek conducts the following: Let by examining a roll of fabric in 48” width and 120 yards in length, the below defects have been determined or marked: You can extend this format for recording number of defects for defect wise. Final inspection is the last steps of garment inspection system. Spot any defects on the factory floor, and avoid costly returns.

Some of the formats are image files. Fabric checker should know common defects found in fabrics and he must recognize defects on the fabric at the time of fabric inspection. In this stage complete garments are inspected by buyer. Fabric inspection is the systematic observation of fabrics to decide if it meets the client specification such as count/construction, color, design, measurement specifications, hand feel, and other specific quality parameters. 1 defect more than 9” 1 x 4 = 4 points.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

4 defect below 3” 4 x 1 = 4 points. Fabric inspection is the systematic observation of fabrics to decide if it meets the client specification such as count/construction, color, design, measurement specifications, hand feel, and other specific quality parameters. Purchase includes pm checklists in excel format for the following 27 equipment types: Quick and easy first article inspection report software with our free first article inspection report (fair) forms, you can manually complete to fill the forms on excel or other spreadsheet software. Download the file after opening it on google drive to use the template.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

Some of the formats are image files. See more ideas about kpi dashboard excel,. Sum up total pieces checked and total defects found in those checked pieces. Spot any defects on the factory floor, and avoid costly returns. A sample 4 point system fabric inspection format has been attached at the bottom.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title fabric inspection report format in excel by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.